Our Building Steps:

1. Permit

2. Excavation with track backhoe, hand-trimmed to shape and structure detail beams, walls, coves, skimmers, and lights.

3. Steel reinforcement in perimeter beams is a box beam with 4 – ½” rebars. Steel is extended out of the beam for attachment to the deck rebar. Skimmers and lights are wrapped in steel for support. Typical wall shell steel is 3/8” rebar on 8” centers throughout. Extra steel is added at break line and all stress points resulting in over 70% of the structure with rebar at 5” on center. Steel rebar is located 3” above bottom of 8” thick pool shell and centered in walls. Deck steel is 3/8” rebar at 12” on center.

4. Gunite used is dry gunite. 6-sack mix, mixed at the jobsite and forced through a hose at 120 p.s.i.. This process results in a cure strength of 4800 p.s.i.. Pool perimeter bond beam is 12” x 14”. Floor and side walls are 8” thick. All overspray and excess gunite will be removed from the jobsite.

5. Standard perimeter tile is typically 6” x 6” band of frost proof tile in owner’s choice of pattern and color. Special tile such as slate or custom tiles are also available for installation. Coping is typically 12” flagstone, travertine, bullnose or limestone is available.

6. All plumbing work is completed by Mastercraft personnel, scheduled 40 pipe is utilized. 2 Skimmers and 2 main drains are plumbed with separate 2” lines. Spa plumbing is looped with up to 3” pipe size. By looping plumbing all spa jets have equal pressure and 2 main drains. We also feature Jandy Lifetime valves which are an extremely durable plastic valve with the greatest flow of any valve available. A minimum of 4 directional return inlets for proper flow and possible heating of the pool. All plumbing is pressure tested to insure there are no leaks and left under pressure during construction.

7. Every pool is equipped with a freeze protector on all pumps to prevent any damage due to freezing temperature conditions.

8. Plaster finish is marblelite with 2 coats hand troweled for as smooth as possible finish, also polished aggregate finish’s and colored plaster are available.

9. Caulking is a self-leveling compound installed between coping and deck and anywhere the deck intersects a structure. This is lightly sanded to cut down on glare and prevent debris while caulk cures.

10. Supervision throughout all phases of the construction is performed by the owner of Mastercraft Pools, J. Ted Rador.

11. After pool is filled, Mastercraft maintains pool for 5 day’s brushing and vacuuming. We balance water chemistry, install pool cleaner and then give complete instructions.

Our Build Process:

1. Layout

1. Layout

Prior to any work being done, we paint the shape of your pool on the ground as a guide for the excavators. You approve the pool’s outline and position prior to the scheduling of the dig.

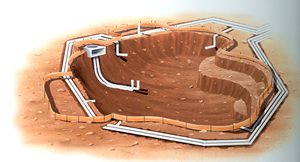

2. Excavation

Our unique excavation specifications include vertically excavated walls and flat floors. This creates a safer, more enjoyable and spacious swimming pool compared to the industry norm. Our excavation crews are equipped with the newest trucks and equipment. This equipment, combined with our training and policies, results in crews that are able to leave your property free of damage, oil spills and any unprofessional mess.

3. Plumbing and Equipment

Your pool plumbing and equipment are the guts of your pool. Done correctly, a pool’s hydraulics will ensure years and years of trouble free enjoyment with minimal maintenance. Special features standard on our pool include dual main drains for safety, a high flow skimmer and looped returns for balanced water flow.

The schedule 40 PVC piping will be buried below your excavated pool forms to ensure long-term integrity. The valves that direct water flow are guaranteed for lifetime, low maintenance, easy to operate, and labeled for simplicity. Water flow is increased by the size of the pump and by the diameter of the piping. We routinely bid against undersized systems that will not provide enough water for good pool circulation, spa action or water feature needs. Compare these features and you will get an idea of a pool company’s desire for long term customer satisfaction.

4. Steel Rebar

Steel rebar is placed throughout your pool on a steel grid pattern. The steel reinforces the tensile strength of your pool’s concrete shell. The vast majority of pool companies use standardized steel specifications driven with the belief that the least expensive is the best. Our steel specifications will be developed and engineered for your particular pool, in your particular soil and with the unique load and stress of your pool design. Our one-pool-at-a-time engineering generates steel plans that will have a grid patterns that are typically 8” apart. Under boulders, near the patio or fences, and in other stress areas, we will place steel on 6” grids. We have never had a structural failure due to too little steel. This includes hundreds of pools on hillsides and with features such as disappearing edges. We will not sacrifice long term durability and peace of mind to save a few dollars!

Your pool is guaranteed for life against any steel rebar rust bleed-through, caused by placing steel too near the concrete surface. This rusting problem is excluded in many warranties but we believe that it is our responsibility to make sure this does not happen.

5. Electrical

Standard Features include a full –sized pool light with remote control abilities. A time clock and control panel will be placed at the equipment for daily, effortless pool system control. Many optional lighting and spa control systems are available to meet your budget and needs.

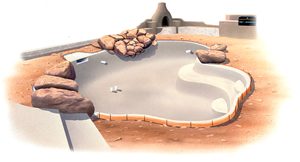

6. Shotcrete/Gunite

We use a special mix of gunite that test to 4000 psi. Industry standards are as low as 3000 psi. Our additional mix adds compaction strength to the concrete shell.

Our pneumatically placed (shot in place with air pressure) shell is a minimum thickness of 6”. In coves and stress areas it is a minimum of 8” thick. Our bond beam and other structural load areas will be 12” minimum thickness. We never come back to the homeowner and charge for additional concrete known as overbreak. (This can add up to several hundred dollars with other pool companies.)

Our lifetime pool shell warranty includes replacing water, chemicals, electricity, and complete repair of any interior or incidental damage should the shell ever develop a crack. We give this extensive warranty because we build pools that last!

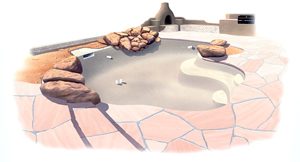

7. Masonry and Rock

Like all the initial phases of construction, our masonry and rock work are built and engineered with long-term durability in mind. Now we add a new criteria—-appearance. Our rock installers and masons are closer to artists than construction workers. You may have chosen our pool because of our design awards, customer service reputation or how our pools look. Now you will see why we shine above our competitors. It comes down to pride in what we do, the attention to detail and the artistry these crews put into their work. The bottom line is if it doesn’t look great, we will do it again until it does. This approach develops crews who do it right the first time!

8. Decking

Tile deck, spray deck, pea gravel decks, pavers, colored concrete — you dream and we can do it. The large horizontal covering we call a pool deck is the most visible part of your pool. A deck must be well built for durability, heat resistance and chip resistance. It must stay in place, withstanding the movement of the soils it is built on.

The artistry of this stage must combine with many important construction issues. Frankly, our deck prices may be slightly higher than many of our competitors. But when you compare the thickness, the footings and the aesthetics, you will probably decide, as we have, that an extra few hundred dollars here is well-spent when it buys a lifetime of practical use and maintenance-free beauty.

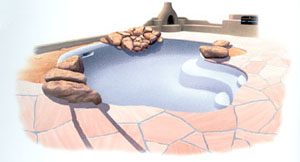

9. Interior Surfaces

9. Interior Surfaces

Again, there are many choices here. Tile surfaces, pebble surfaces, stone surfaces, plaster and an array of colors and textures allow for the pool to be individualized for your décor and needs. These surfaces must resist a wide variety of chemicals, constant attacks from hard water scaling and the sun. Our project manager will discuss the features, benefits and costs. Whatever your choice, we pledge the highest quality in materials and workmanship.